◆ Features

With extremely high surface hardness and chemical resistance

It has extremely high surface hardness and chemical resistance, and can transmit ultraviolet rays to wavelengths ranging from mid-infrared.

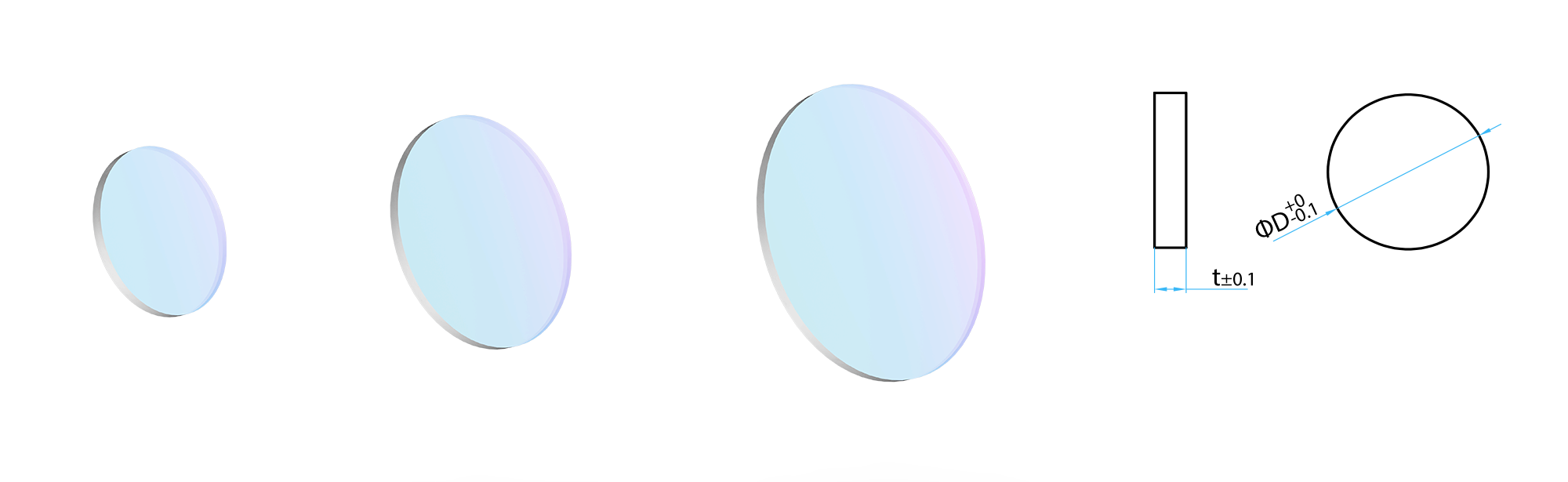

Thinner and more durable than standard glass window panes

Offer an anti-reflection coating option covering wavelengths from 350 to 5000 nanometers.

◆ General Specifications

Materials | sapphire |

Coating film | Uncoated |

Board surface accuracy | 2λ |

Depth of parallelism | <1' |

Surface quality | 80-50 |

Effective diameter | An inscribed circle with an area that is 90% of the area of a square of the same size. |

◆ Application

Airborne/Shipborne Multispectral Observation System: Designed for infrared night vision devices, laser sights, etc., it maintains stability in low-temperature observation windows or in high-salt spray marine environments.

Semiconductor manufacturing and inspection equipment: As substrate for epitaxy (such as in SOS technology) or as windows for lithography machines, they can withstand strong acid/strong alkali cleaning environments, and the crystal orientation accuracy is strictly controlled.

Deep-sea probe observation window: Can withstand high pressure (>100 MPa) and salt corrosion environment, replacing traditional quartz glass to extend service life.

Dimensional requirements: The outer diameter and thickness shall be determined based on the spatial layout of the optical system and the beam size.

Mounting configuration: All circular lenses from Mloptic can be mounted on standard lens sleeves, fixed lens mounts, and various coaxial mounting plates.

Coating requirements: The coating quality must comply with general specifications for optical coatings. Scratches or contamination on the coating should be avoided as they may affect the anti-reflection performance.

Cleaning taboos: Avoid cleaning with corrosive solvents such as strong acids and alkalis, as they may damage the anti-reflection coating and glass substrate. It is recommended to use optical-specific cleaning agents (e.g., isopropanol, diethyl ether) and gently wipe with soft lint-free cloths or lens paper to prevent surface scratches.

Transportation and storage: Optical surfaces must be strictly protected during transportation. When packaging, direct contact between protective films and optical surfaces is prohibited to prevent contamination by foreign substances or scratches.