◆ Features

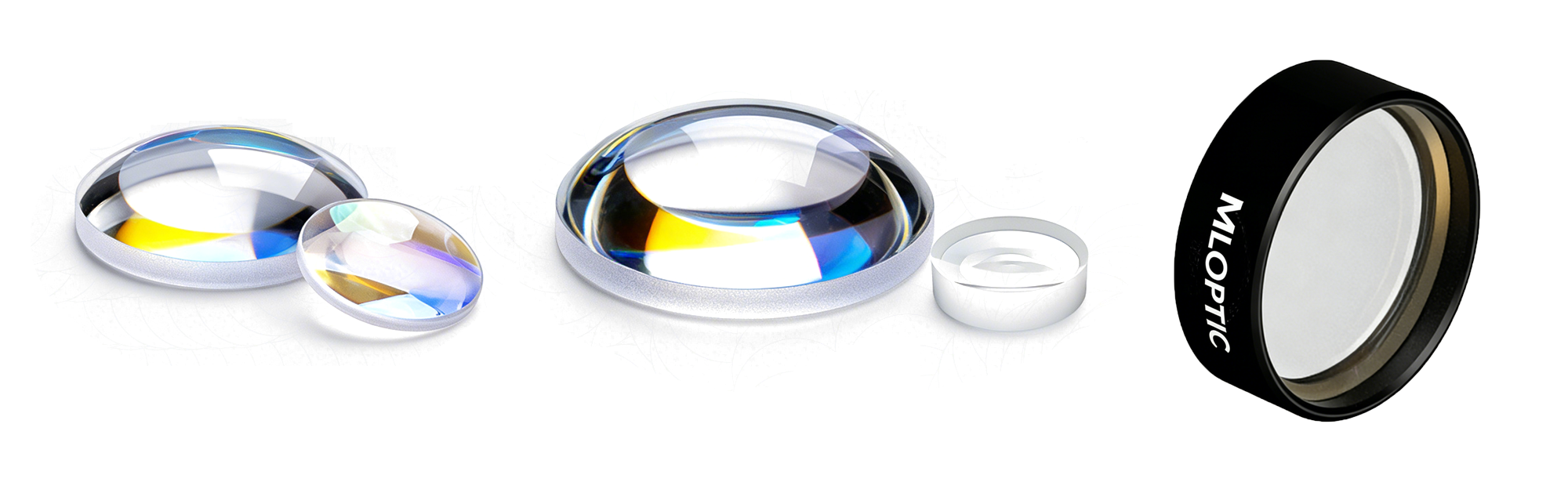

It adopts ultraviolet fused silica glass, which has better uniformity and a lower coefficient of expansion compared to N-BK7 glass, and is mostly used in the ultraviolet and near-infrared wavelength ranges.

It features a high clear aperture and strict control over surface shape accuracy, ensuring low wavefront distortion and high transmittance.

Stable material performance

Strictly controlled optical precision

High light transmittance (>90%) and low light absorption rate

◆ Common Specifications

Material | Corning 7980 |

Design Wavelength | 589 nm |

Refractive index | 1.4585 nm |

Surface Quality | 20-10 |

Coating | Uncoated |

Surface Flatness | S1< λ/2@633nm S1< 1.5λ@633nm |

Material | N-BK7 |

Design Wavelength | 587.6 nm |

Surface Quality | 40/20 |

Coating | BBAR Coating |

Reflectivity | Ravg<0.5%@350-700nm |

Clear Aperture | >90%CA |

◆ Applications

Industrial Imaging Systems

Scientific Optics

Precision Instruments

Low-Light Environments

Precision optical imaging systems

Laser collimation and beam shaping devices

Scientific Research and Experiment

Dimensional requirements: Determine the outer diameter and thickness according to the spatial layout of the optical system and the beam size.

Mounting compatibility: All circular lenses from MLOPTIC can be mounted on MLOPTIC standard lens sleeves, fixed lens mounts and various coaxial mounting plates. Customers can choose the optimal mounting method for different application scenarios.

Cleaning taboos: Do not use acidic/alkaline solvents for cleaning. It is recommended to gently wipe with anhydrous ethanol and lint-free swabs.

Coating Maintenance: For uncoated products, both the front and back surfaces of the lens have reflection losses, so the transmittance is approximately 90%.

Packaging and storage: Should be packaged individually and stored in a dry and clean environment to prevent mildew and friction. The recommended environmental conditions are temperature 15°C-35°C and relative humidity <60%.

Spherical plano-convex lenses have chromatic aberration, and their focal lengths vary with wavelength.

Material | N-BK7 | Clear Aperture | >90% CA |

Diameter | Φ12.7 mm | Diameter Tolerance | 0.0/-0.1mm |

Center thickness | 3.5 mm | thickness tolerance | ±0.1 mm |

Edge thickness | 1.8 mm | Radius of curvature | 12.9mm |

Design Wavelength | 587.6 nm | Refractive index | 1.5168 nm |

Focal length | 24.9 mm | Focal Length Tolerance | ±1% |

Back focal length | 22.6 mm | Coating | BBAR Coating |

Center Deviation | <3′ | Surface Quality | 40/20 |

Surface Flatness | S1< λ/2@633nm S2<3λ/2@633nm | Reflectivity | Ravg<0.5%@350~700nm |

Angle of incidence | 0° |

Material | Corning 7980 | Clear Aperture | ≥90% CA |

Diameter | Φ50.8 mm | Diameter Tolerance | 0.0/-0.1mm |

Center thickness | 14.058 mm | thickness tolerance | ±0.1 mm |

Edge thickness | 3.0 mm | Radius of curvature | 34.7 mm |

Design Wavelength | 589 nm | Refractive index | 1.4585 nm |

Focal length | 75.6 mm | Focal Length Tolerance | ±1% |

Back focal length | 65.96 mm | Coating | Uncoated |

Center Deviation | ≤3′ | Surface Quality | 20/10 |

Surface Flatness | S1< λ/2@633nm S1< 1.5λ@633nm | F-number | 1.5 |

Material | Corning 7980 | Clear Aperture | ≥90% CA |

Diameter | Φ12.7 mm | Diameter Tolerance | 0.0/-0.1mm |

Center thickness | 6.660 mm | thickness tolerance | ±0.1 mm |

Edge thickness | 3.0 mm | Radius of curvature | 7.335mm |

Design Wavelength | 589 nm | Refractive index | 1.4585 nm |

Focal length | 16 mm | Focal Length Tolerance | ±1% |

Back focal length | 11.43 mm | Coating | Uncoated |

Center Deviation | ≤3′ | Surface Quality | 20/10 |

Surface Flatness | S1< λ/2@633nm S1< 1.5λ@633nm | F-number | 1.3 |