◆ Features

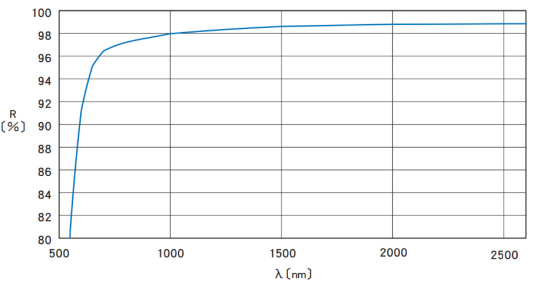

The infrared dominator: Reflectance > 98% in the 750 nm–25 μm band, making it the top choice for infrared optical systems.

Near - zero transmission: Unreflected light is completely absorbed by the gold film, avoiding stray light interference.

Coating structure: A very thin chromium film is deposited on the substrate to enhance the adhesion of the gold film.

Substrates: Glass and silicon substrates. Silicon substrates have higher thermal conductivity and stronger heat resistance.

◆ Common Specifications

Material | BK7 | |||||

Hard glass (Pyrex®etc.) | ||||||

Silicon crystal | ||||||

Coating | Cr (chrome)+Au (Gold) | |||||

Parallelism | <3' | |||||

Surface Quality (Scratch-Dig) | 40-20 | |||||

Clear Aperture | 90% of diameter or circle that internally contacts 90% square of diameter | |||||

Laser Damage Threshold | 1.2 kW/cm²(CW laser) | |||||

◆ Applications

Infrared spectroscopy analysis: The gold film is suitable for FTIR spectrometers, covering the 2–20 μm molecular vibration spectrum.

High - temperature laser processing: Silicon-based gold film mirrors can withstand high - power CO₂ lasers (10.6 μm).

Applications in mid - and far - infrared optical systems such as deep - space infrared imaging.

◇ Ultraviolet/visible light systems: Aluminum films or ultraviolet - enhanced aluminum films are preferred.

◇ Broad - spectrum visible light - near infrared: Silver films are preferred, but environmental humidity needs to be controlled.

◇ Mid - and far - infrared: Gold films are recommended, and silicon substrates can improve heat dissipation.Users can precisely match the type of metal film according to spectral requirements, budget, and environmental conditions to achieve the optimal balance between the performance and cost of the optical system.

Characteristics | Aluminum Film Mirrors | Silver Film Mirrors | Gold Film Mirrors |

Optimal wavelength band | Ultraviolet - visible light (250–700 nm) | Visible light - near infrared (450–2000 nm) | Mid - and far - infrared (750 nm–25 μm) |

Peak reflectance | 87–90% (visible light) | >97.5% (visible light) | >98% (infrared) |

Environmental stability | Medium (requires a protective layer) | Low (prone to sulfidation) | High (corrosion - resistant) |

Damage threshold | 0.25 J/cm² (10 ns pulse) | 0.5 J/cm² (under the same conditions) | 1.2 kW/cm² continuous laser |

| Material | BK7 | Clear aperture | >90% CA |

| Diameter | 20 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 5 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Matte side |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | BK7 | Clear aperture | >90% CA |

| Diameter | 25 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 5 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Fine Ground |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | BK7 | Clear aperture | >90% CA |

| Diameter | 30 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 5 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Fine Ground |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | BK7 | Clear aperture | >90% CA |

| Diameter | 40 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 6 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Fine Ground |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | BK7 | Clear aperture | >90% CA |

| Diameter | 50 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 8 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Fine Ground |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | BK7 | Clear aperture | >90% CA |

| Length | 20 mm | Length Tolerance | 0/-0.1 mm |

| Thickness t | 5 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Matte side |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | BK7 | Clear aperture | >90% CA |

| Length | 25 mm | Length Tolerance | 0/-0.1 mm |

| Thickness t | 5 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Matte side |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | BK7 | Clear aperture | >90% CA |

| Length | 30 mm | Length Tolerance | 0/-0.1 mm |

| Thickness t | 5 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Matte side |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | Hard Glass | Clear aperture | >90% CA |

| Length | 50 mm | Length Tolerance | 0/-0.1 mm |

| Thickness t | 8 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Fine Ground |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | Silicon Crystal | Clear aperture | >90% CA |

| Diameter | 30 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 3 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Matte side |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | Silicon Crystal | Clear aperture | >90% CA |

| Diameter | 40 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 4 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Matte side |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |

| Material | Silicon Crystal | Clear aperture | >90% CA |

| Diameter | 50 mm | Diameter Tolerance | 0/-0.1 mm |

| Thickness t | 5 mm | Thickness Tolerance | ±0.2 mm |

| Coating | Cr+Au | Reflectivity | >99% |

| Angle of Incidence | 0°–45° | Back Surface | Matte side |

| Operating wavelength | 0.75–25 μm | Parallelism | —— |

| Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

| Laser Damage Threshold | 1.2 kW/cm² CW laser |