◆ Features

High Reflectivity: The mirror features an optimized multi - layer coating for different wavelengths, delivering excellent reflectivity performance. After multiple reflections by several mirrors, the light intensity experiences only a slight attenuation, ensuring the efficient utilization of laser energy during transmission.

High-Power Laser Resistance: This mirror is fabricated using an anti-laser coating technology, enabling it to withstand continuous irradiation of high-power lasers. The multi-layer dielectric film structure makes the mirror highly resistant to damage from high-energy laser impacts, thereby extending its service life and making it suitable for high-power laser environments.

Specific Angle of Application: The designed incident angle is 45°±3°. Within this angular range, the mirror can maintain excellent optical performance. When used at angles other than 45°, the reflectivity may decrease.

High-Precision Optical Parameters: The substrate surface has a flatness of λ/10, a parallelism of less than 3 arcminutes. These parameters effectively ensure the accuracy and stability of laser reflection, reduce light scattering and loss, and guarantee high-quality laser beam reflection.

◆ Common Specifications

Material | Fused Silica |

Coating | Dielectric Multi-layer Coating |

Incident Angle | 45°±3° |

Surface Flatness | λ/10 |

Parallelism | <3' |

Clear Aperture | 90% of the diameter |

Rear Surface | Polished |

◆ Applications

High-Power Pulsed Laser Systems: Applicable to high-power pulsed Nd-YAG lasers optical systems. In scientific research, industrial processing, and other fields, it is used for laser cutting, welding, drilling, and other processes. By precisely reflecting the laser beam, it enables high - precision material processing.

Excimer Laser Systems: Used for ArF (193 nm) and KrF (248 nm) excimer lasers. In photolithography technology, it accurately reflects the laser beam onto silicon wafers, achieving fine photolithography of chip circuits and promoting the development of the semiconductor industry.

YAG Laser Harmonic Applications: Can be used for reflecting the fundamental wave (1064 nm) to the 4th harmonic (266 nm) of YAG lasers. It plays an important role in fields such as laser display and medical cosmetology.

|  |

|  |

|  |

|  |

|  |

◇ Wavelength Matching: Select the corresponding model according to the actual wavelength of the laser in use.

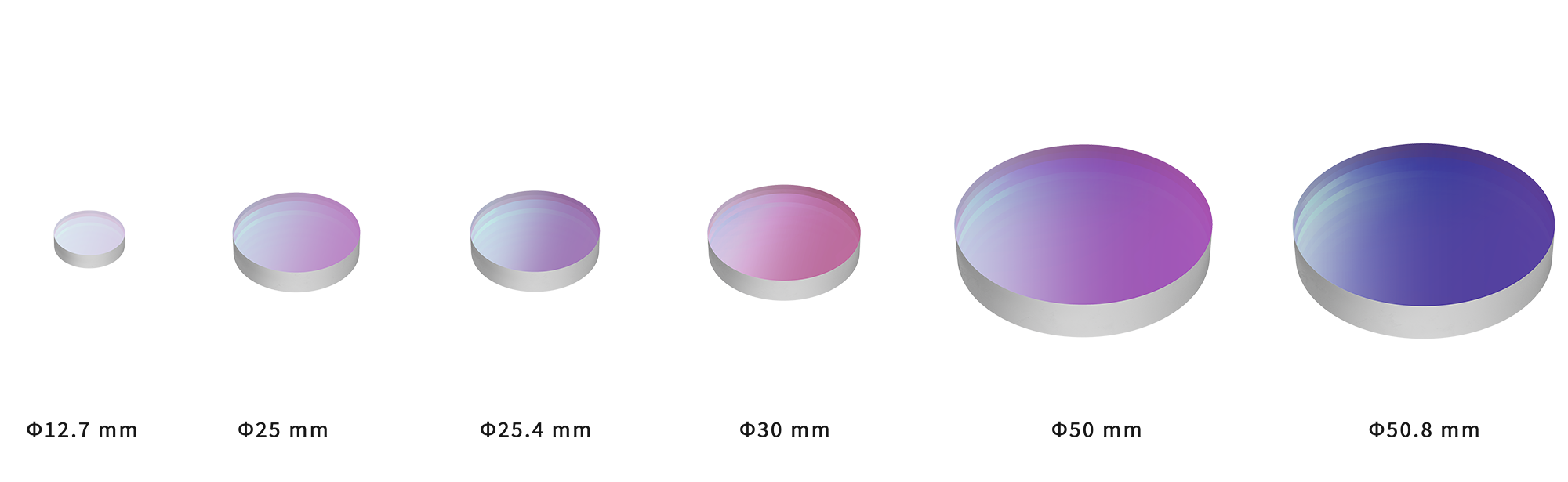

◇ Size Requirements: Determine the outer diameter and thickness based on the spatial layout of the optical system and the beam size.

◇ Reflectivity Requirements: For applications with strict requirements on light attenuation, give priority to models with higher reflectivity. For example, in a laser resonator, high reflectivity can enhance the resonance effect of the laser and increase the laser output power. In such cases, try to select a mirror with a reflectivity>99%.

◇ Consideration of Laser Damage Threshold: Estimate the energy density of the incident laser and ensure that the laser damage threshold of the selected mirror is higher than this energy density. In laser application scenarios with high pulse energy, choose a mirror with a relatively high laser damage threshold to prevent the mirror from being damaged by the laser.

◇ Energy Density Control: Ensure that the energy density of the incident laser beam does not exceed the laser damage threshold before use. When focusing the beam through a lens or concave mirror (resulting in a narrower beam waist), the increased energy density may damage the mirror due to exceeding its tolerance.

◇ Transmitted Light Management: For high-power applications, even light with a transmittance below 1% may pass through the mirror. Shield the rear surface of the mirror to block stray light and prevent interference with surrounding equipment or personnel.

◇ Fluorescence Phenomenon: UV-grade mirrors may exhibit fluorescence in the ultraviolet spectral range. Special attention is required in applications sensitive to fluorescence (e.g., fluorescence microscopy or spectroscopy).

◇ Polarization Effects: The reflectance wavelength characteristics of multi-layer dielectric coatings vary with the polarization state of the incident beam. Compared with S-polarized light, P-polarized light typically has lower reflectance and a narrower reflection spectrum. The reflectance values specified in technical specifications are the average of the reflectances of P-polarized and S-polarized light.

◇ Wavelength Applicability: Reflectance may decrease when used outside the design wavelength range. Mirrors must be selected strictly according to the actual operating wavelength.

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >95% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 193 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 2 J/cm²( *Angle of incidence 0°, laser pulse width 20 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >95% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 193 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 2 J/cm²( *Angle of incidence 0°, laser pulse width 20 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >95% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer | Back Surface | Polished |

Operating wavelength | 193 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 2 J/cm²( *Angle of incidence 0°, laser pulse width 20 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 248 nm | Parallelism | <3' |

Operating wavelength | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 248 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

| Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 248 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ12.7 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 3 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 257 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm² ( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 257 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 257 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

| Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 257 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 257 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50.8 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer | Back Surface | Polished |

Operating wavelength | 257 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 4 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatnes | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm | Parallelism | <3′ |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

| Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm(AR) | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm(AR) | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >98% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 266 nm(AR) | Parallelism | <3' |

Surface Quality | 40/20 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ12.7 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 3 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 343 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 343 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.5 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 343 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 343 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm² ( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 343 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50.8 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer | Back Surface | Polished |

Operating wavelength | 343 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 355 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 355 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 355 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 355 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Surface Flatness |

Operating wavelength | 355 nm | Parallelism | <3' |

Surface Quality | 20/10 | Polished | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 355 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 8 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ12.7 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 3 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 515 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26 J/cm² ( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 515 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT * | 26 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 515 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 515 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 515 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50.8 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 515 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 532 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26.5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 532 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26.5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 532 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26.5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 532 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26.5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 532 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26.5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 532 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 26.5 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ12.7 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 3 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1030 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1030 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1030 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1030 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1030 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50.8 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1030 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm² ( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1064 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/ cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1064 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1064 nm | Parallelism | <3' |

Surface Quality | 10/5 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ25.4 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1064 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ30 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 5 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1064 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||

Material | Fused Silica | Clear aperture | >90% CA |

Diameter | Φ50 mm | Diameter Tolerance | 0/-0.1 mm |

Thickness | 8 mm | Thickness Tolerance | ±0.2 mm |

Reflectivity | >99% | Angle of Incidence | 45°±3° |

Coating | Dielectric Multi-layer Coating | Back Surface | Polished |

Operating wavelength | 1064 nm | Parallelism | <3' |

Surface Quality | 20/10 | Surface Flatness | λ/10(@633 nm) |

LIDT* | 28 J/cm²( *Angle of incidence 0°, laser pulse width 10 ns, repetition frequency 20 Hz) | ||